February

26

2019

Polyplast grows its presence in the wood industry

In Quebec, forests are sacred. Everyone in Quebec has nature at heart for one reason or another. Whether it’s for their fun activities, the wildlife they shelter or simply because they’re a nice sight on a daily walk, forests are crucial to many people. Not surprising, considering forests cover nearly half the area of the province (761,100 km²)!

And forests aren’t just important because of our relationship to them. They also make up a large part of our provincial and national economy. In Quebec alone, there are more than 290 wood processing plants in areas such as pulp and paper, sawn lumber, veneer and plywood, wood turning and processing.

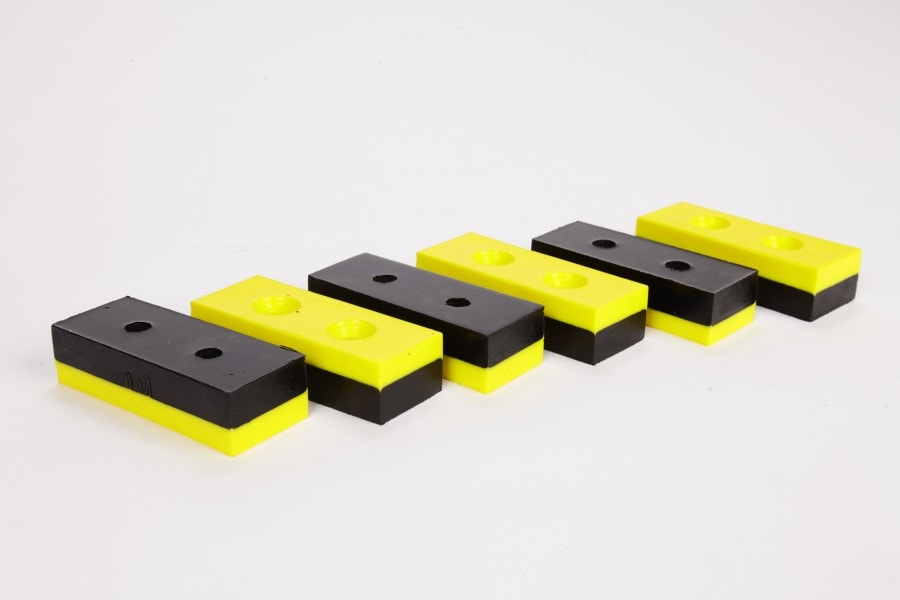

For that reason, Polyplast is proud to help develop and maintain wood processing plants through its innovative polyurethane products. Polyurethane is highly impact-resistant, so it is often used as a shock absorber in industrial machinery. For the past several years, Polyplast has developed shock absorber systems that are tailored to the realities of wood processing plants, such as bounce limitations and the frequency and speed of impact.

We also design wheel and roller covers. In fact, we have a room dedicated entirely to manufacturing this type of product, meaning that we can guarantee precision, durability, and high-quality finishes to wood processing plants.

Take a look at our projects to see some of our designs.

We want to continue supporting and developing innovative solutions for the forestry industry. That’s why Polyplast is participating in the Montréal Wood Convention this year.

The Montréal Wood Convention: the annual gathering of professionals from Quebec and overseas

The Montréal Wood Convention includes conferences, an exhibition room and networking activities. It’s a can’t-miss event: we’ll be there on March 20 and 21 at the Fairmont The Queen Elizabeth in Montréal.

Generally, we work through four steps with our clients. First, we evaluate the machinery and determine the parts that need to be replaced or protected. Next, we identify the problem and determine any constraints. We then develop a model based on this information. Finally, we start production.

We look forward to starting the process with you at booth 81 at the Montréal Wood Convention!

Sources:

https://mffp.gouv.qc.ca/wp-content/uploads/chiffres-cles.pdf

.JPG)